Our Fabrication capabilities include:

- Standard commercial structural steel

- Heavy industrial steel

- Heavy plate work (box beams) sub arc welding

- Large span trusses (box, tapered and curved parabolic)

- Conveyor frames

- Components for drilling equipment

- Custom miscellaneous projects (we don’t back down from unique projects)

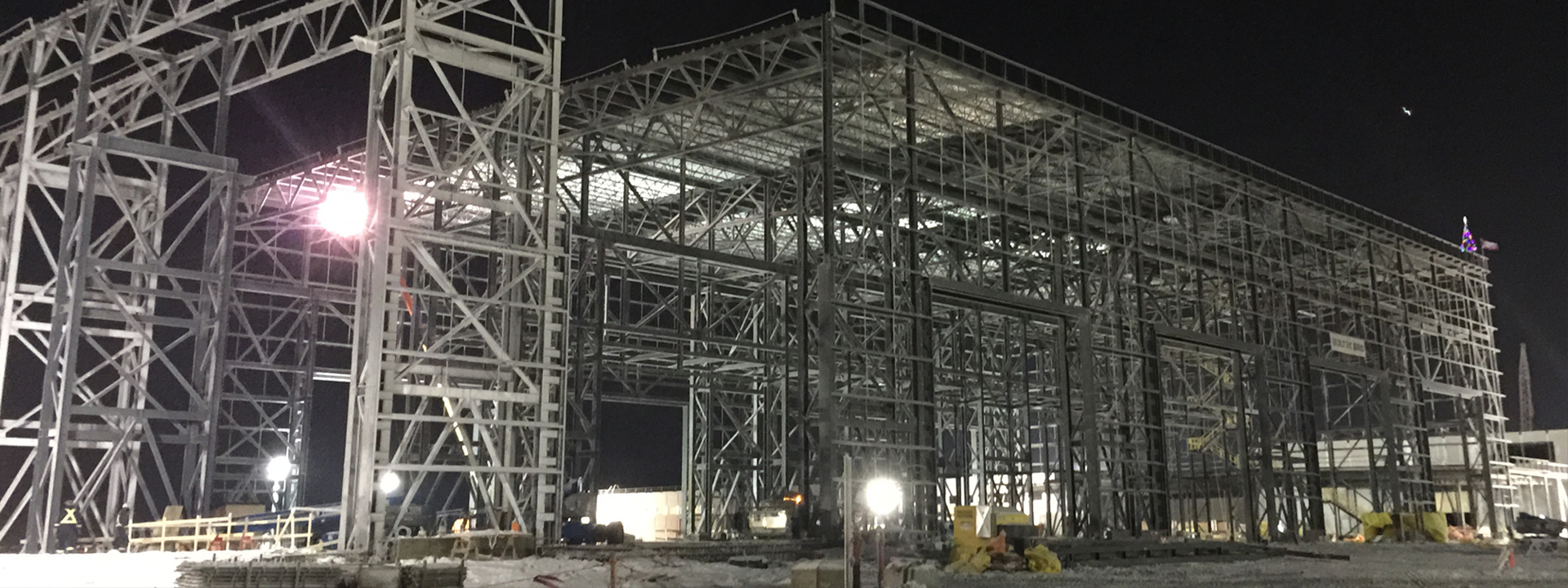

Standard Structural Steel

- MSE has three beam lines, two of which are fully automated. These beam lines provide an efficient method for cutting and drilling fabricated steel. Fabrication equipment receives details directly from the Tekla model to ensure materials are made correctly.

- MSE has a standard ITP protocol that governs the fabrication process. The ITP process is tailored to each client’s expectations, ensuring a high quality product.

- MSE uses Fabsuite to control the fabrication process from inventory, to cut lists, to shipping. All aspects of fabrication are well documented and controlled through this software.

- We have implemented a barcode system to track pieces as they travel through the fabrication process.

- MSE detailers have developed many standard connections, to create a consistent product that helps our site erection team assemble the steel with minimal welding.

- MSE has a highly skilled work force, including several Level 1 & 2 inspectors and many Red Seal tradesmen.

- MSE employees are skilled in the fabrication of miscellaneous metals. We have a newly installed laser layout table, which greatly increases the speed and accuracy of miscellaneous project production.

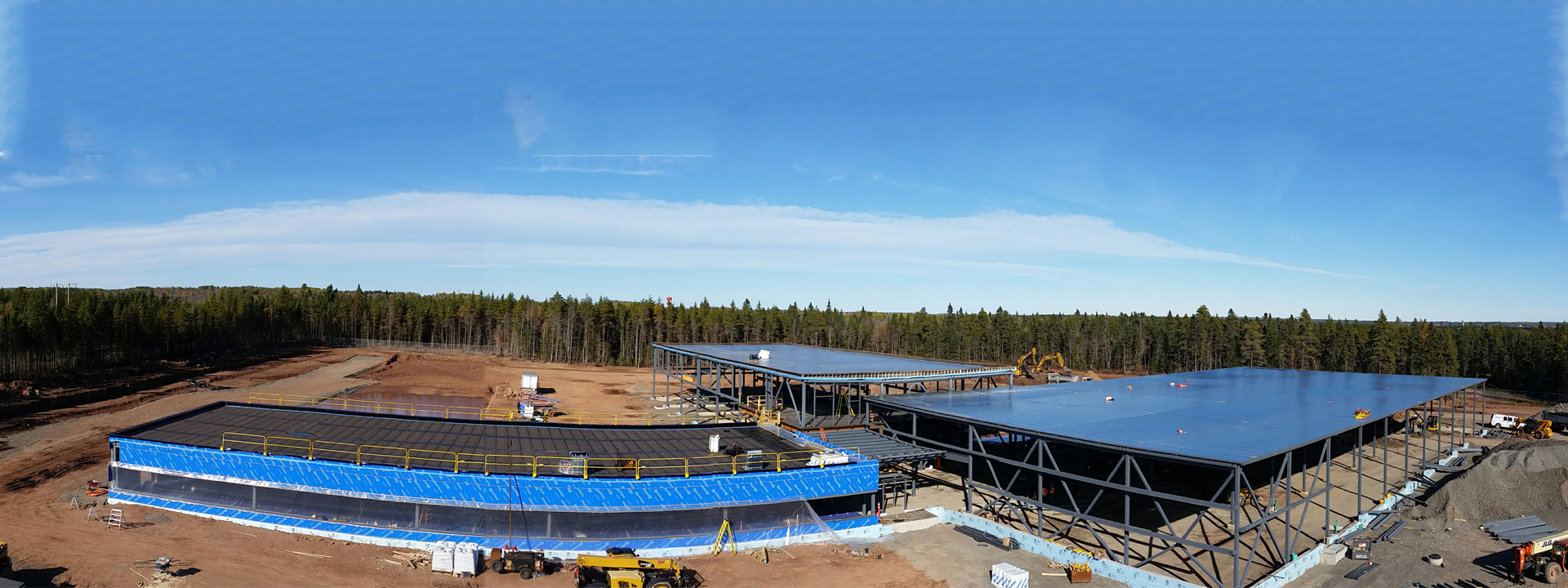

Heavy Industrial Steel

- We have large work areas where we can assemble larger modular pieces.

- All automated equipment aids in ensuring that all components fit like a glove.

- Our experienced workforce can adapt to new challenges.